Non-prehensile transportation using robotic arms presents a promising solution for the service industry. Such applications require robotic arms to be reactive, safe, and flexible enough to navigate uncertain and complex environments while maintaining the transported objects' stability. However, existing methods are often ineffective in these scenarios. In this letter, a risk-adaptive motion planning framework is proposed for safe and resilient non-prehensile object transportation. Specifically, the risk is evaluated via the predicted time-to-collision (TTC), and is responded to through a three-level safety mechanism, i.e., replanning, safe stop planning, or hardware-level emergency stop. Notably, the first two levels rely on an efficient trajectory generator that integrates constrained path planning, trajectory parameterization, and refinement. In this generation pipeline, a constrained path planner provides global guidance in complex environments, serving as a high-quality initialization for the subsequent coarse-to-fine trajectory optimization. In addition to the TTC-triggered replanning, this framework incorporates a periodic replanning strategy to proactively adapt to dynamic goal switching and environmental changes. Finally, the framework is evaluated through extensive experiments.

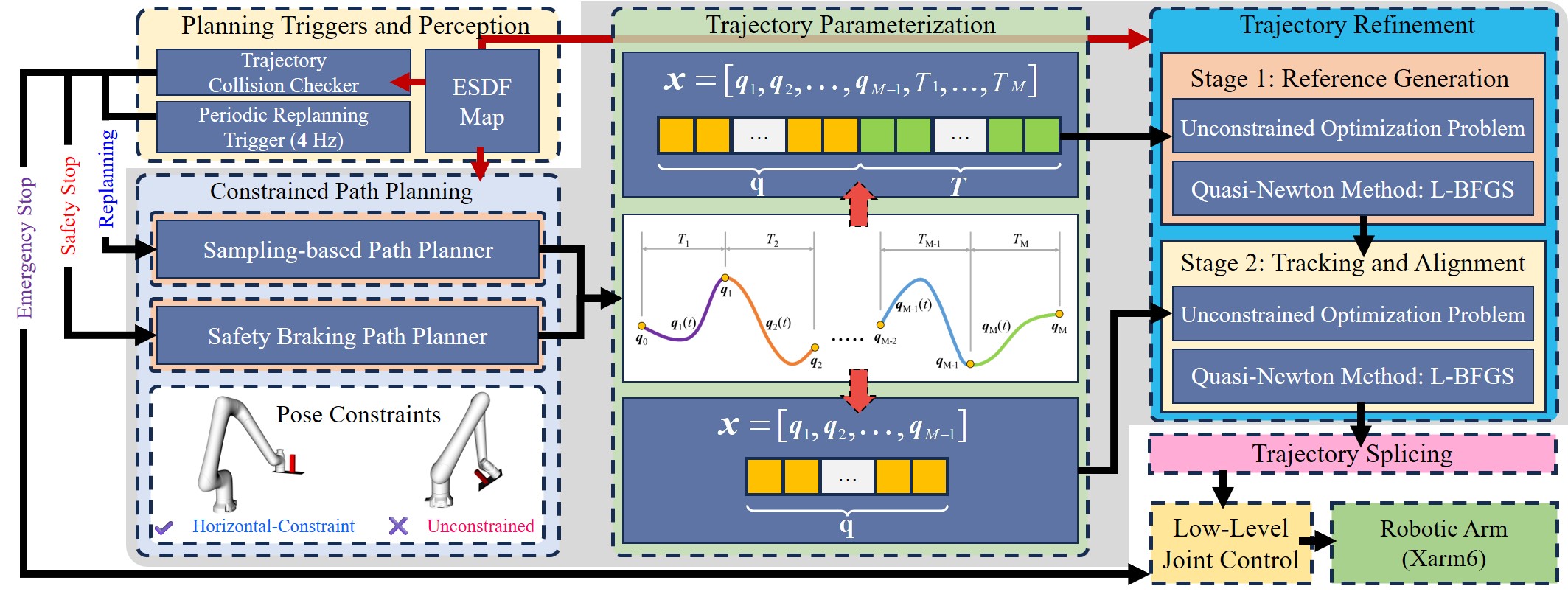

Fig. 2. Risk-adaptive motion planning framework, featuring a dual-triggering mechanism (periodic and safety-driven) and a complete trajectory generation pipeline, which integrates constrained path planning, trajectory parameterization, and trajectory refinement.

Note: All videos are shown at real-time speed (1x) unless otherwise stated.

We compare our method (left) with a strong reactive baseline (right) adapted from an MPC approach [1] in four scenarios.

Ours (An open space)

Baseline (An open space)

Ours (A narrow passage)

Baseline (A narrow passage)

Ours (A table obstacle)

Baseline (A table obstacle)

Ours (A cluttered scene)

Baseline (A cluttered scene)

The performance of the replanning framework is evaluated in dynamic environments.

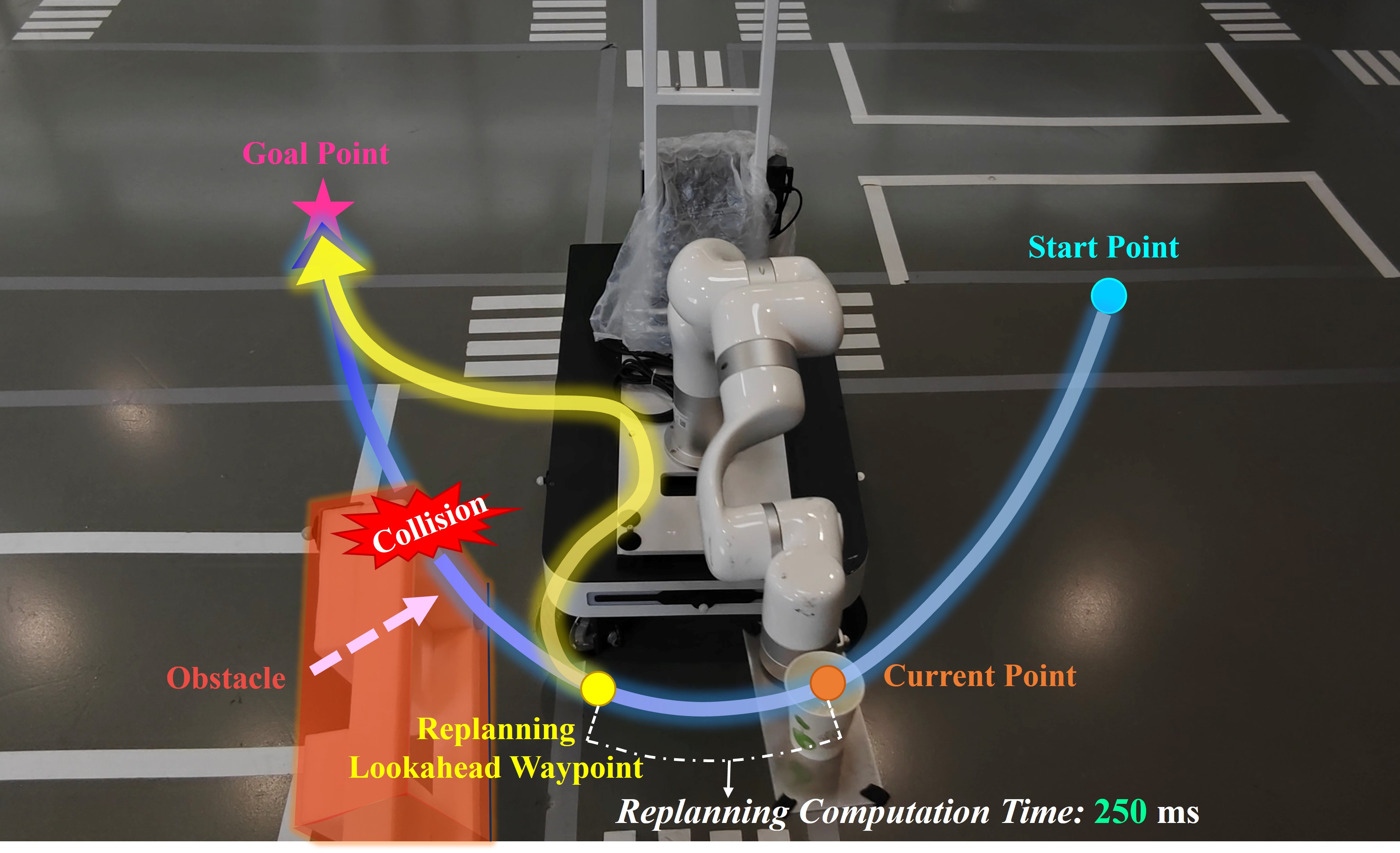

The replanning maneuver in response to a sudden obstacle

The safety-stop maneuver in response to a sudden obstacle

Non‑prehensile transportation in a dynamic environment (scene updated every 3s)

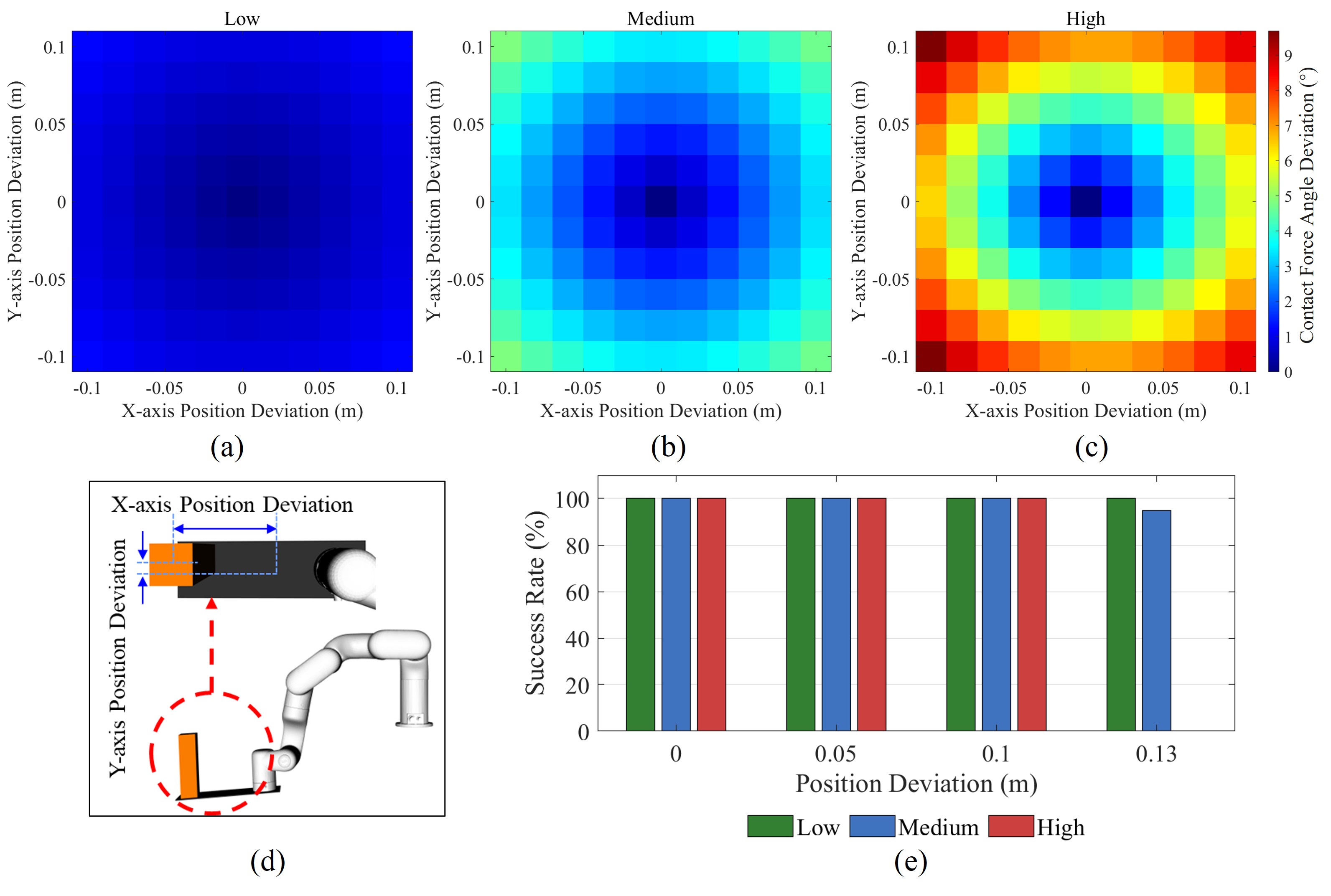

We evaluate the robustness of our method against CoM displacement under varying levels of motion aggressiveness.

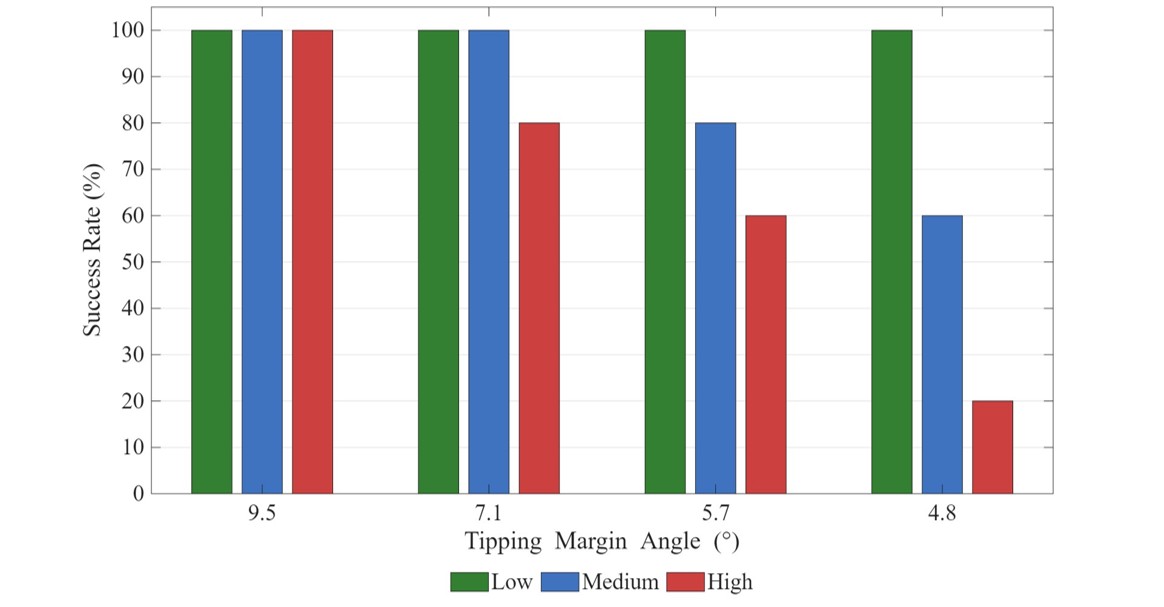

Fig. 3. Robustness evaluation against position deviations, tested at three aggressiveness levels (low, medium, and high). (a-c) Heatmaps show the deviation between the actual and nominal contact force angles, resulting from the applied CoM position deviations. (d) The experimental setup. (e) Corresponding success rates.

Low aggressiveness,

Deviation: (x = 0.0 m, y = 0.0 m)

Medium aggressiveness,

Deviation: (x = 0.0 m, y = 0.0 m)

High aggressiveness,

Deviation: (x = 0.0 m, y = 0.0 m)

Low aggressiveness,

Deviation: (x = 0.05 m, y = 0.0 m)

Medium aggressiveness,

Deviation: (x = 0.05 m, y = 0.0 m)

High aggressiveness,

Deviation: (x = 0.05 m, y = 0.0 m)

Low aggressiveness,

Deviation: (x = 0.1 m, y = 0.0 m)

Medium aggressiveness,

Deviation: (x = 0.1 m, y = 0.0 m)

High aggressiveness,

Deviation: (x = 0.1 m, y = 0.0 m)

Low aggressiveness,

Deviation: (x = 0.13 m, y = 0.0 m)

Medium aggressiveness,

Deviation: (x = 0.13 m, y = 0.0 m)

High aggressiveness,

Deviation: (x = 0.13 m, y = 0.0 m)

We further increased the motion aggressiveness and conducted non-prehensile transportation experiments. It can be observed that the manipulator leverages rotational motion to effectively mitigate the shear force acting on the transported object.

Non-prehensile transportation with extreme aggressiveness

For the cuboid (5 × 5 × 20 cm) with a tipping margin angle β ≈ 14.0°, the constraint violation is insufficient to induce tipping. However, for a slender cuboid 2.5 × 2.5 × 30 cm, β ≈ 4.8°, the risk of tipping increases significantly.

Finally, the proposed framework is evaluated in a series of challenging real-world scenarios. First, we examine the performance across various tipping margin angles and motion aggressiveness levels. The following video is shown at 4x speed.

Low aggressiveness,

Transported Object (2.5 × 2.5 × 15 cm)

Medium aggressiveness,

Transported Object (2.5 × 2.5 × 15 cm)

High aggressiveness,

Transported Object (2.5 × 2.5 × 15 cm)

Low aggressiveness,

Transported Object (2.5 × 2.5 × 20 cm)

Medium aggressiveness,

Transported Object (2.5 × 2.5 × 20 cm)

High aggressiveness,

Transported Object (2.5 × 2.5 × 20 cm)

Low aggressiveness,

Transported Object (2.5 × 2.5 × 25 cm)

Medium aggressiveness,

Transported Object (2.5 × 2.5 × 25 cm)

High aggressiveness,

Transported Object (2.5 × 2.5 × 25 cm)

Low aggressiveness,

Transported Object (2.5 × 2.5 × 30 cm)

Medium aggressiveness,

Transported Object (2.5 × 2.5 × 30 cm)

High aggressiveness,

Transported Object (2.5 × 2.5 × 30 cm)

Fig. 4. Success rates across various tipping margin angles and motion aggressiveness levels.

Subsequently, the reactivity and robustness of our method are evaluated by executing non-prehensile transportation of a slender bottle, milk cartons, and a partially filled water cup in a quasi-static environment. Notably, the implementation remains based on the cuboid model (5 × 5 × 20 cm) without object-specific parameter tuning.

Transport a slender bottle

Transport milk cartons

Transport a partially filled cup of water

Non-prehensile transportation with frequently changing goal points

To demonstrate the versatility and hardware-agnostic nature of our framework, we conducted further experiments on a Rokae XMate CR20 robotic arm. The results show that our method can be readily applied to different hardware with minimal adaptation.

Non-prehensile transportation in extremely cluttered environments

Transport two slender water bottles

Transport three slender water bottles

Transport two objects stacked vertically (front view)

Transport two objects stacked vertically (side view)

This letter presents a risk-adaptive framework for reliable non-prehensile transportation in quasi-static environments. To ensure reactivity and resilience, the framework integrates a three-level safety mechanism with proactive periodic replanning. These mechanisms rely on a hierarchical trajectory generator that incorporates constrained path planning, trajectory parameterization, and a two-stage trajectory optimization process. Extensive experiments demonstrate the framework's efficiency and robustness. Future work will: 1) extend the framework to mobile manipulation for large-scale transportation; 2) improve computational efficiency via parallel computing; and 3) enhance system robustness against uncertainties.